2024-08-30 https://www.aluminum-coils.com/a/8011-aluminum-sheet-for-pp-cap-materials.html

In the packaging industry, the choice of materials plays a critical role in ensuring product safety, integrity, and shelf-life. One such high-performance material that is increasingly gaining fame is the 8011 aluminum sheet. This versatile alloy is particularly revered for its applications in producing polypropylene (PP) caps, providing numerous advantages that enhance the efficiency and effectiveness of packaging solutions.

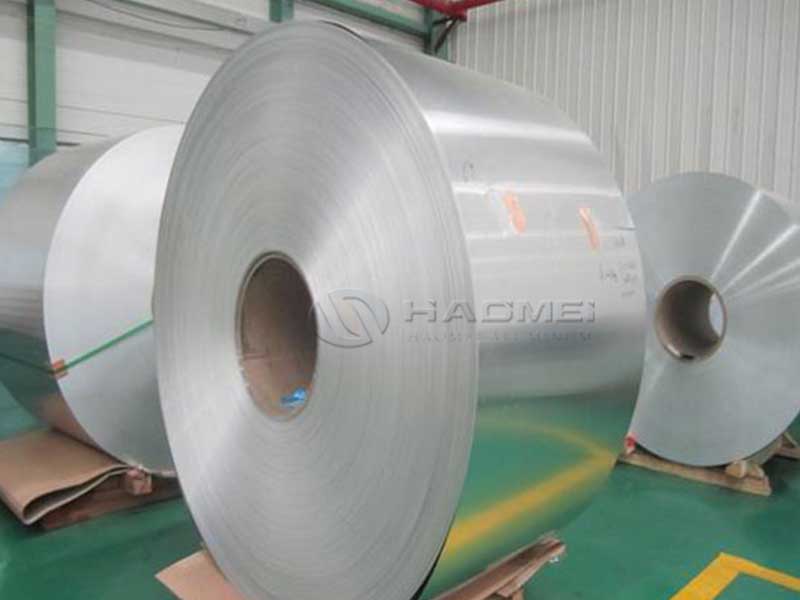

What is 8011 Aluminum Sheet?

8011 aluminum sheets belong to a series of aluminum alloys that contain iron and lithium in their composition. It is primarily used for applications requiring substantial resistance to corrosion and formability. The thickness of the 8011 aluminum sheet can vary, but it commonly ranges from 0.018 mm to 0.035 mm, which strikes a perfect balance between flexibility and strength.

Why Choose 8011 Aluminum Sheet for PP Cap Materials?

1. Lightweight and Durable

One of the most significant advantages of the 8011 aluminum sheet is its lightweight nature. Utilizing lightweight materials like aluminum in PP cap production not only enhances processing efficiency but also reduces transportation costs. The high durability of 8011 aluminum ensures that the caps maintain their structural integrity throughout their lifecycle, from production to point-of-sale.

2. Excellent Barrier Properties

8011 aluminum sheets provide excellent barrier properties against moisture, gases, and UV rays. In conjunction with PP materials, this creates an effective sealing solution that preserves the freshness of the products inside. Whether it's for beverage, food packaging, or pharmaceuticals, ensuring optimal protection is critical, and the combination of PP and aluminum shines in this regard.

3. Corrosion Resistance

The 8011 aluminum alloy offers significant resistance to corrosion, which is vital for cap applications, especially in humid or moist environments. This property helps in prolonging the life cycle of the product, reducing the risk of contamination that could compromise the integrity of the enclosed products.

4. Enhanced Aesthetic Appeal

Aesthetics plays a crucial role in packaging. Aluminum sheets can easily be treated through various processes like anodizing, lacquer coating, and printing, allowing manufacturers to create high-quality, visually appealing caps. The 8011 aluminum sheet shines with its smooth finish, which also aids in easy branding and custom designs.

5. Eco-Friendly Option

As businesses are becoming more eco-conscious, the sustainability of packaging materials comes to the forefront. Aluminum is infinitely recyclable without loss of quality, making the 8011 aluminum sheet an eco-friendly option for PP cap production. This sustainability can significantly enhance a company's image among consumer bases that prioritize environmentally responsible practices.

Applications of 8011 Aluminum Sheet in PP Cap Manufacturing

The diverse combination of PP and 8011 aluminum sheets opens doors to a myriad of applications in various industries. These include:

- Food and Beverage Cap Sealing: Transitioning with new regulations and enhancing consumer safety entails ensuring that food and beverages maintain their quality. The 8011 aluminum sheet serves as a reliable barrier, protecting contents from external contaminants.

- Pharmaceutical Packaging: In the pharmaceutical sector, maintaining drug potency is paramount. The 8011 aluminum sheet contributes to reliable sealing mechanisms for medicine bottles and containers.

- Cosmetics and Personal Care: Brands that focus on cosmetic cap sealing benefit hugely from the aesthetic advantages and corrosion resistance provided by the 8011 aluminum sheet.