2024-10-19 https://www.aluminum-coils.com/a/aluminum-closures.html

In today’s rapid-paced market, effective packaging solutions are crucial for sustaining product integrity and ensuring customer satisfaction. One of the leading options in the packaging industry is aluminum closures, which offer a unique blend of durability, versatility, and aesthetic appeal.

What Are Aluminum Closures?

Aluminum closures are specialized caps or lids made from aluminum that are used to seal bottles, jars, and other containers. These closures are renowned for their lightweight properties and chemical resistance, making them an excellent choice for packaging a variety of products ranging from beverages and cosmetics to pharmaceuticals.

Why Choose Aluminum Closures?

-

Superior Barrier Properties: Aluminum is impermeable to light, gases, and moisture, which protects the contents of your product from spoilage or contamination. Whether it's a craft beer or a luxury skincare serum, aluminum closures maintain the desired quality until the consumer is ready to use it.

-

Sustainability: With the growing emphasis on environmentally friendly practices, aluminum closures stand out as a sustainable solution. Aluminum is highly recyclable, and using Aluminum Closure Sheets contributes to closed-loop production strategies, where recycling rates can exceed 90%. This commitment to sustainability not only helps protect the environment but can also enhance brand loyalty.

-

Customization and Design Flexibility: The flexibility in design offered by aluminum closures is unmatched. Whether you prefer a sleek metallic finish or a colorful printed design, aluminum provides the opportunity to create eye-catching packaging that can attract consumers. Ensuring your product stands out on the shelf is important, and aluminum closures can be tailored to meet these branding needs.

-

Cost-Effectiveness: Despite its premium look and capabilities, aluminum is comparatively cost-effective when packaged tightly in a competitive market. The lightweight nature of aluminum closures also leads to reduced transportation costs, contributing positively to the overall budget for packaging.

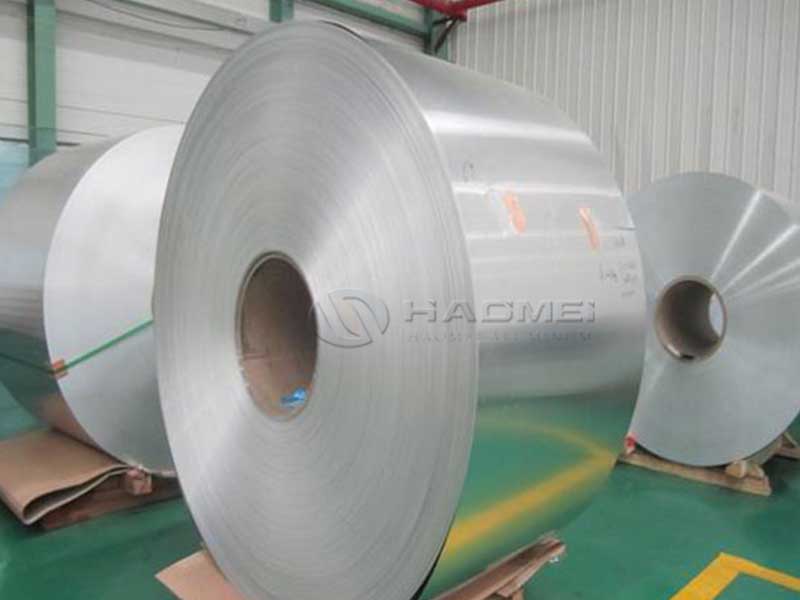

Application of Aluminum Closure Sheets

Central to the manufacturing of aluminum closures is the use of Aluminum Closure Sheets. These specialized sheets are engineered to create robust, high-quality closures suitable for diverse applications. The minimization of material waste during production, combined with their lightweight composition, ensures that manufacturers can optimize their resources effectively.

The Manufacturing Process

The production of aluminum closures begins with Aluminum Closure Sheets, which undergo processes like shearing, punching, and forming to produce reliable and functional finishes. Quality assurance at each stage of the process guarantees that each closure exhibits optimal performance, catering to the demands of modern consumers for quality and aesthetic value.

Future of Aluminum Closures in Packaging

With advancements in technology and a shifting consumer landscape that prioritizes sustainability, aluminum closures will continue to evolve. Innovations in coatings and sealing technologies promise improved performance, while increased recycling initiatives aim to reduce the environmental impact further. As a result, more brands in distinct sectors are likely to recognize the invaluable qualities offered by aluminum closures.