2025-05-07 https://www.aluminum-coils.com/a/mill-finished-aluminum-coil-thin-foil-make-food-container.html

Mill Finished Aluminum Coil Thin Foil: Revolutionizing Food Containers from the Inside Out

In today’s fast-paced world, convenience without compromising quality has become the mantra of food packaging. At the heart of many food containers lies an unsung hero—mill finished aluminum coil thin foil. But what makes this material not just indispensable, but uniquely suited to preserving, protecting, and packaging our favorite meals?

The Magic Behind Mill Finished Aluminum Coil Thin Foil

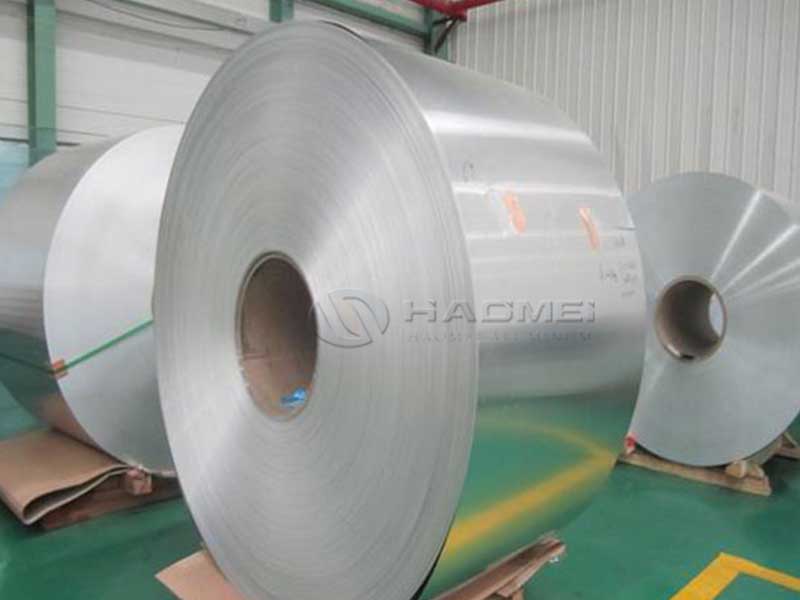

When aluminum is “mill finished,” it means the coil undergoes a precise manufacturing process leaving it smooth, untreated, and ready for further applications. Unlike anodized or coated surfaces, mill finished aluminum foil preserves the metal’s natural purity, resulting in exceptional malleability and reflective properties.

From a mill finishing perspective, the thin gauge aluminum foil destined for food containers presents unique challenges. Achieving the necessary gauge consistency across the entire coil is paramount, as even minor variations can impact the formability and leak-proof integrity of the final product. We constantly monitor the rolling process, adjusting tension and lubricant application to minimize gauge deviations and surface imperfections. Maintaining a pristine surface finish is also critical; scratches or blemishes can compromise the foil's appearance and potentially create weak points. This demands meticulous cleaning and careful handling throughout the entire production line, from the initial casting to the final coil packaging. The temper of the foil is also crucial, balancing strength and formability to allow for efficient deep drawing into container shapes without tearing or cracking.

Beyond the mill, the downstream processes is vital. The specific forming techniques used by the container manufacturer (e.g., deep drawing, impact extrusion) influence our choice of alloy and temper. We work closely with our clients to ensure the foil's characteristics align perfectly with their production capabilities. For instance, a slightly harder temper might be preferred for a more rigid container, while a softer temper allows for more intricate shapes. Ultimately, the quality of the mill-finished coil directly impacts the efficiency and cost-effectiveness of the entire food container manufacturing process, and ultimately, the consumer's experience. A consistently high-quality coil leads to fewer rejects, less waste, and a superior final product.

This raw finish makes aluminum coil thin foil incredibly versatile. Its thickness is carefully controlled to be thin enough for easy shaping, yet strong enough to maintain structure—perfect for forming the rigid or flexible shapes needed in food containers.

Why Thin Aluminum Foil is the Ideal Material for Food Containers

Barrier ProtectionThe thin foil acts as a nearly impenetrable shield against light, moisture, oxygen, and bacteria. This keeps food fresh longer, reduces spoilage, and retains the state of moisture and aroma inside each container.

Thermal Conductivity for Uniform HeatingAluminum conducts heat efficiently, meaning food in aluminum foil containers heats evenly whether baking, grilling, or reheating. This thermal uniformity prevents hotspots, protecting flavor and texture.

Sustainability EdgeAluminum foil is 100% recyclable without loss of quality. Mill finished thin foil used in food containers means fewer plastic alternatives — encouraging environmental responsibility among manufacturers and consumers.

Lightweight and Space-EfficientThe thin gauge of mill finished aluminum foil means containers are lightweight yet sturdy enough to hold a variety of foods. Their stackability maximizes storage and transportation efficiency—a critical factor in modern food logistics.

Technical Nuances That Elevate Mill Finished Aluminum Foil

Because it is produced directly from the mill, this foil has no surface coating or additional layers. Unlike laminated foil options that might incorporate plastics or adhesives, mill finished aluminum coil thin foil ensures a pure aluminum surface that can be recycled easily, avoiding landfill contamination. It offers excellent ductility, allowing manufacturers to create unique container shapes, or embossed patterns to strengthen edges without the need for added materials.

Its natural metallic finish also lends containers an appealing aesthetic, conveying a fresh, clean image climbers associate with quality and hygiene.

Rethinking Food Storage with Mill Finished Aluminum Coil Thin Foil

Beyond preservation, these foils represent a paradigm shift towards combining engineering efficiency with ecological mindfulness. For businesses in the foodservice sector, prioritizing mill finished aluminum coil foil for containers aligns with consumer demand for sustainable, high-performing packaging.

Consumers also benefit practically from ready-to-use containers that can transition directly between refrigerator, oven, grill, and tabletop — seamlessly blending convenience with responsibility.