2025-01-14 https://www.aluminum-coils.com/a/aluminium-foil-fin.html

When we think of aluminium foil, the first images that may flash through our minds are kitchens stocked with rolls used for wrapping food, insulating our leftovers, or baking them to perfection. However, an often-overlooked application lies in the remarkable innovation known as the aluminium foil fin. This technical marvel has multifaceted functions that range from thermal management in heavy industry to applications in HVAC systems – functions that may just ignite the designer in you.

Unveiling the Functions of Aluminium Foil Fins

At its core, the aluminium foil fin serves primarily as a means for heat transfer. The structural design is intrinsically tied to its lightweight nature and superior thermal conductivity. By increasing the surface area for heat exchange, these lightweight fins become essential components in various systems.

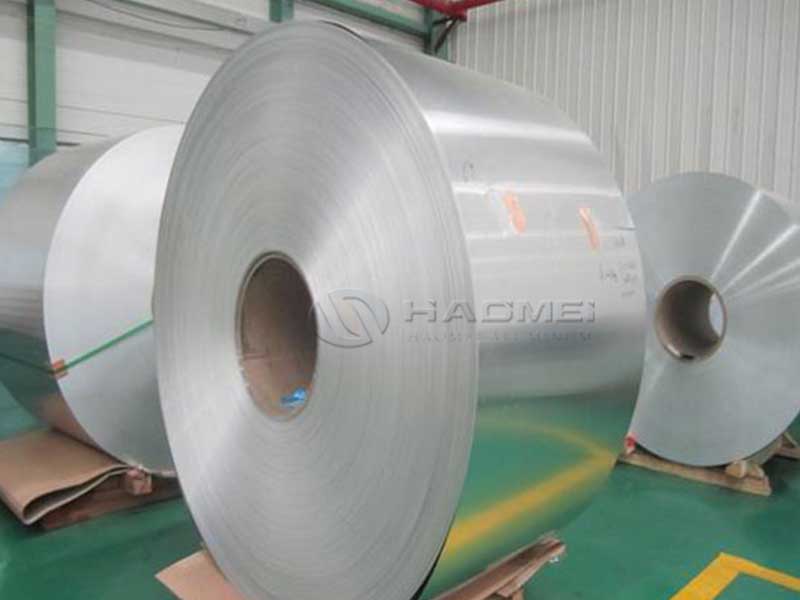

As a technical staff member focusing on the production of aluminum foil at our plant, I've developed a keen appreciation for the subtleties involved in creating even the seemingly simple "aluminum foil fin," a component often overlooked in the larger manufacturing process. While it might seem like just a small, pre-cut piece of foil, the fin's performance is directly tied to the quality of the starting material. We meticulously control gauge consistency and surface finish to ensure optimal heat transfer properties. Slight variations in thickness can significantly affect the fin's efficiency, leading to uneven cooling in applications like heat sinks. My role involves troubleshooting inconsistencies – a poorly formed fin, for instance, might point to issues with our slitting machinery or imperfections in the original foil roll. the interplay between roll tension, cutting blade sharpness, and even ambient humidity is crucial for producing a consistently high-quality fin.

Beyond the technical aspects, I find the sheer volume of aluminum foil fins we produce daily quite fascinating. Seeing a seemingly endless stream of these small components – destined for a myriad of uses from electronics to industrial equipment – underscores the crucial role our factory plays in global manufacturing. It's a tangible reminder that even the smallest part contributes to the larger functional whole. Recently, I was involved in a project optimizing the fin's design for a new client, improving its surface area without compromising on material usage. This sort of problem-solving, finding the sweet spot between efficiency and cost

1. Thermal Heat Exchangers

One of the most prominent applications of aluminium fins is in the design of thermal heat exchangers. These devices are pivotal in assisting engines, refrigerators, and air conditioning systems in manipulating thermal energy efficiently. The addition of aluminum foil fins effectively enhances the heat exchange process. The thinly-layered fins allow for rapid thermal dissipation, making them indispensable in high-efficiency systems.

2. HVAC Systems Efficiency

Aluminium foil fins are vital contributors to the efficiency of HVAC units. By managing the flow of warm and cool air within ducts effectively, these fins optimize energy consumption. The use of fins assists in minimizing energy waste, reflecting a growing industry trend toward sustainability. Their lightweight construction not only promotes lower overall system weight but also adds to easier installation and tooling.

Technical Clarity: The Aerodynamics Behind Its Shape

Diving deeper technically, the design of aluminium foil fins may capture diverse forms like louvered, straight, or even folded configurations. Each variation is tailored for specific scientific principles that govern airflow and heat distribution. Particularly, the aspects of aerodynamic efficiency and thermal resistance play an integral role.

An essential insight lies in the thermodynamic theory where each configuration maintains unique thermal boundary layers. An exemplary design is a wavy or louvered fin, which disrupts the airflow adeptly—exposing maximum surface area to exchange heat while mitigating turbulence. This thoughtful engineering leads toward improving the overall performance characteristics of desirable heat exchangers and air conditioning systems.

Diverse Applications in Various Industries

While the majority of us associate aluminium foil fins with constructing appliances, their uses extend beyond domestic applications. Here are some additional innovative applications to consider:

-

Automotive Manufacture: Aluminum foil fins in an engine bay are fundamental in cooling systems, ensuring optimal performance during operation. Overheating can jeopardize engine health, which makes GPU-engineered fins essential components in automobiles.

-

Electronics Cooling: As electronics evolve and trends towards miniaturization persist, efficient cooling mechanisms become vital. Engineered aluminium fins surface in modern circuit boards, leading to better performance due to effective thermal management, safeguarding the integrity and longevity of advanced electronic devices.

-

Renewable Energy Applications: Furthermore, the role of aluminium foil fins expands even more ly in renewable resources, such as solar thermal panels. Learning how to best manage heat gains and prevent overheating can lead to significantly improved system efficiency.